Equipment / Spartan SS1950

SPARTAN SS1950

Stand-On Track Loader

One of our largest stand-on track loaders, delivering 2,000 lb ROC in a 44.6" width for unmatched power and maneuverability. Built to dominate demanding jobs while fitting where traditional loaders can't.

-

44.6” Wide, Powerful Mini Track Loader

-

2,000lbs Rated Operating Capacity

-

Yanmar 4TNV86CT Diesel Engine EPA 48.3HP

-

Bosch Rexroth Hydraulic Piston Pump

-

Poclain Plunger (Piston) Driving Motor

-

21.1 Gallon Multifunctional Control Valve

-

Hydraulic Auxiliary Flow 21.1 GPM

-

HC Joystick and Multifunctional Valve for Smooth Operating

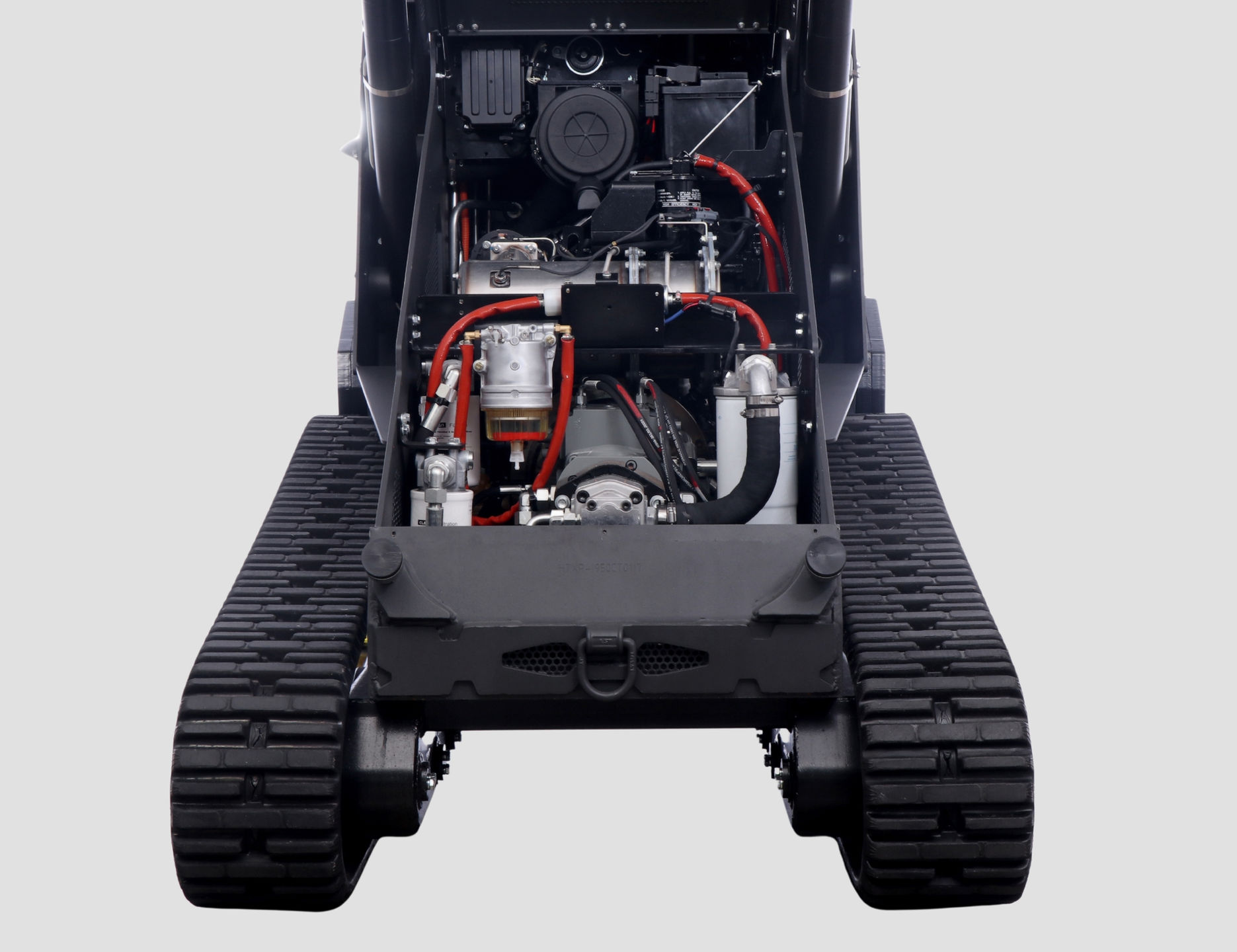

engine and performance

At just 44.6" wide, the SS1950 maintains true compact versatility—navigating tight spaces between buildings, fence lines, and confined job sites with ease. This optimized width delivers full-size loader performance in spaces where competitors can't operate.

The SS1950 is powered by a 48.3HP Yanmar 4TNV86CT EPA-certified diesel engine, delivering robust performance with lower emissions. This 4-cylinder powerhouse provides exceptional torque for demanding tasks while maintaining fuel efficiency—backed by Yanmar’s legendary reliability in compact equipment.

The plunger driving motor delivers unmatched hydraulic performance, handling up to 5,800 psi for extreme power and reliability. Outperforming standard motors, it ensures stronger force, smoother operation, and extended durability—even in rugged terrains and heavy-duty applications. Built for efficiency and endurance, it’s the ultimate choice for demanding tasks.

The SS1950 features a Bosch Rexroth piston pump, delivering unmatched hydraulic efficiency and responsive control. Renowned for reliability in demanding applications, this high-pressure pump ensures consistent power delivery to attachments while withstanding extreme workloads with minimal maintenance.

Hydro Control’s upgraded multifunctional valve delivers precision micro-operation for smooth, responsive control. Its innovative design enables simultaneous boom lifting and attachment operation—powering demanding tools like mulchers without performance loss. Engineered for seamless hydraulic integration, it ensures optimal flow control for both delicate tasks and heavy-duty applications.

The ergonomic grip and hydraulic pilot control joystick layout minimize fatigue during long shifts. Hydro Control's pilot valve enables instant speed adjustments while maintaining precise steering response. Every control is optimized for efficiency and safety in demanding terrain.

VMENG offers dual auxiliary hydraulic ports with 21.1 GPM high flow controlled by a lever for power attachments and 2.7 GPM low flow with joystick button control for precision work. This system enables compound movement operation.

With strong load resistance and wear reduction, this design enhances durability, minimizes maintenance, and ensures seamless compatibility with CII attachments from other brands.

The heavy-duty boom with protected internal hydraulic lines offers enhanced durability, making it ideal for high-intensity tasks with greater longevity and reduced maintenance needs.

VMENG's non-aggressive tread minimizes ground disturbance without sacrificing traction. Integrated anti-vibration technology ensures operator comfort during long shifts. Built with rugged materials, these tracks deliver smooth, durable performance across all terrains - protecting surfaces while maintaining machine productivity.

The quick pressure relief mechanism prevents residual pressure buildup in attachments during disconnection, ensuring easy reattachment. Combined with case strain protection that avoids overflow, this system maintains hydraulic integrity while enabling fast, safe attachment changes even under high-pressure conditions.

The floating function allows the loader arms to follow ground contours automatically, ensuring consistent contact for finishing work like grading or snow removal. This feature reduces operator effort while improving surface quality, with the system maintaining optimal downforce without manual adjustments.

With a smooth, rust-resistant finish that resists scratches, it maintains a lasting, professional look for a tough and polished appearance.

The independent chassis, with a tank-style design, evenly distributes weight for enhanced stability and durability, while anti-vibration tracks improve comfort and reduce operator fatigue.

safety and comfort

The suspended standing platform combines heavy-duty spring absorption with elevated visibility. Its dampened design reduces fatigue on rough terrain while providing clear sightlines to the worksite and attachment points—ensuring precise coupling and total control without blind spots or guesswork during operation.

The integrated digital monitor displays essential machine vitals in real time: engine speed, oil pressure, coolant temperature, battery voltage, and operating hours. This instant access to critical data helps operators maintain optimal performance while preventing potential issues before they occur.

The parking lock engages automatically when the machine shuts off, with optional manual activation. This dual-mode system securely maintains position even on slopes, preventing unintended movement during stops or while parked on inclines.

The boom lock engages during operation to temporarily disable hydraulic movement, instantly freezing the boom position when activated. This allows safe personnel access or precise load adjustment without risking accidental contact from hydraulic drift or control errors.

The operator-worn emergency kill switch automatically shuts down the machine if the tether is detached—stopping all functions instantly if the operator falls or moves beyond safe range. This failsafe protection prevents runaway equipment situations, ensuring immediate shutdown during slips, falls, or loss of control.

The 3-point contact rule ensures safe climbing on and off the machine by keeping two hands and one foot in constant contact with steps/handholds. This simple but critical practice prevents slips and falls during entry and exit.

High-intensity LED lights dramatically improve nighttime visibility, illuminating worksites and pathways for safer operation in low-light conditions. Their bright, focused beams enhance spatial awareness while reducing eye strain—ensuring confident machine navigation and hazard detection after dark.

The auxiliary hose guide secures hydraulic lines in proper alignment, preventing tangles and abrasion from branches or debris. By maintaining smooth hydraulic flow and protecting hoses from damage, it extends component lifespan while eliminating safety hazards from loose or whipping hoses.

warranty and serviceability

VMENG backs your investment with a comprehensive 2-year warranty covering both parts and labor. This industry-leading protection ensures worry-free operation.

Thoughtful engineering provides easy access to all critical components—including air, fuel, and hydraulic filters, plus pumps, batteries, and valves. This streamlined layout simplifies routine maintenance and servicing, reducing downtime and keeping your machine running at peak performance with minimal effort.

Removable side panels provide full access to the engine bay and hydraulic components, simplifying maintenance and inspections.

VMENG’s maintenance-free track system combines sealed rollers and automatic tensioning to withstand extreme conditions. The rugged, pre-lubricated rollers and self-adjusting mechanism maintain perfect track tension—eliminating grease intervals and manual adjustments while extending undercarriage lifespan.

Integrated tie-down points provide secure anchoring during transport, keeping the loader firmly positioned on trailers. These reinforced anchor points prevent shifting or movement, ensuring safe and stable transit.

Strategically placed grease fittings are positioned within easy reach, streamlining routine maintenance. These clearly marked zerk fittings require no contortions or tool extensions, cutting lubrication time in half while ensuring proper component care.

Discover More

In a crowded market, VMENG mini track loaders reign supreme